How to Read Completion Report Oil Gas

Well Completion – Oil & Gas Wells

Overview

Well completion is a series of processes performed on a drilled and cased oil & gas well, in order to fix it for product. Information technology involves running production tubing and downhole tools (east.g. mandrels, downhole safe valve, pump, etc.) every bit required. It besides involves perforating and stimulating the well, commonly known as the frac. It can also include acidizing and nitrogen circulation as needed.

While at that place are many hole types and completion methods, this document will focus on horizontal tight oil & gas (shale) wells that typically utilise cased hole completion.

In the early phases of oil exploration and production, companies targeted large pools of oil in highly permeable rock. In the lower 48 states of the United states and Canada, those pools of oil have been largely tapped. New technologies and techniques now make it possible to cost-effectively extract oil & gas from source rock, shale. When companies were targeting pooled oil, the greatest determinant of success was finding oil. However, in the age of tight oil, the locations of shale are well known. There are certainly meaning differences betwixt various shale basins and grades forth those basins, where geology plays an of import office. However, operations has become increasingly disquisitional to E&P success in the era of shale.

In the shale era, E&Ps drill far more wells per acre. In some ways this is analogous to the car's transition from hand-built to mass production. Simply like automobile manufacturing, the shift to a well manufacturing model drives massive productivity gains, enabling far more cost-effective extraction of hydrocarbons. Where this analogy fails is that oil wells have far more than variability because of the variability of their geology. East&Ps will therefore have very standardized processes, but the formulas volition vary from well to well. Think of information technology as stamping out largely identical wells, but dynamically tuning the completion (east.g. perforation blueprint, etc.) for each well.

In guild to reach a manufacturing procedure in conjunction with well-specific optimization, we will see an increasing accent on well completion. We will run across an increased emphasis on capturing and blending well data, operational information and lithology using big data and car learning tools, to optimize completion on-the-fly. In brusk, oil well completion will become increasingly important to East&P success.

What is Well Completion?

Well completion is a series of steps–depending upon the completion method–performed subsequently the drilling and casing phase, that enable to well to produce hydrocarbons. The main goals are to stimulate the well to maximize product, and running tubing to enhance the well'south lifespan and ease of maintenance.

The Well Completion Process

Well completion is a phase of the well lifecycle between drilling and product; essentially preparing a drilled and cased well for product. This certificate focuses on tight oil & gas wells, since completion is more complex, expensive, and important for these wells.

The well completion process typically involves the following steps:

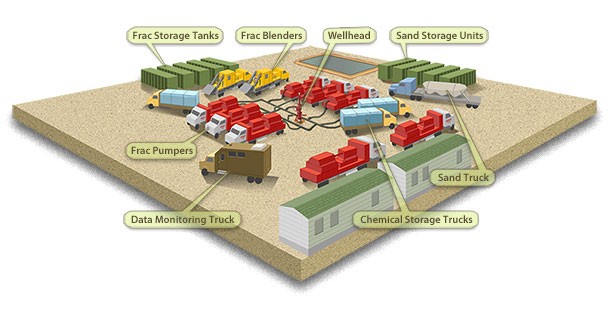

one. Well Training: This step is analogous to the rig up phase of drilling. Various elements of the frac are assembled: sand, fluids, blenders, pumps, chemicals, data van, etc. This is also the step where the well is flushed with a mix of water and acid to clean out the well in grooming for the frac.

Source: FracFocus.ca

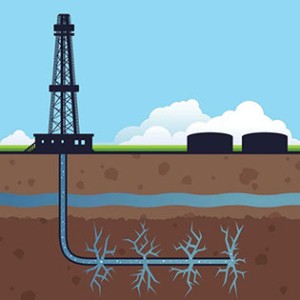

2. Stimulation: Also known every bit hydraulic fracturing or the frac (industry insiders) or frack (general public). Using methods such as plug and perf, the diverse stages are isolated then that service providers can perforate and frac the well, 1 phase at a time. The frac involves pumping down a perforation gun to create holes in the casing to interface with the surrounding rock. So a combination of fluid (h2o mixed with surfactants, etc.) and proppant (e.k. sand) are pumped at very high pressure level into the well. The water cracks or fractures the surrounding rock. Rock fractures typically extend 250-500 feet from the wellbore, with the longest recorded fracture existence less than 600 meters. The proppant included in the frac slurry travels into the fracture and props the fissures open up so that oil & gas tin menstruum through them into the wellbore. Stage counts have been increasing lately, with wells often having 100-200 stages now.

3. Drill-out: This is the removal of whatever material used to isolate stages during the frac process, often done using a coiled tubing drill-out method. In a plug-and-perf method of stimulation, a service provider drills through the plug that was used to isolate the various stages. Some operators use a dissolvable plug, just at this time, information technology appears that the drill-out method remains about popular.

(Source: DrillEng Group)

4. Flowback or Put Online: This is the process of bringing the well to production. Information technology may also include shutting in or soaking the well, which some believe increases production and EUR (estimated ultimate recovery), or lifetime production of the well.

Well Completion: Materials Management

Materials Management during the completion process involves the timely purchasing, commitment and storage of all materials required for the completion procedure, or more than specifically for the frac process. About materials are simply ordered and delivered on fourth dimension. As a result of longer laterals and growing phase counts, wells are consuming more proppant and fluid (water). Each of these critical materials has their own unique challenges, and with shut down costs of $100,000 – $250,000 per day, you do not want to incur stoppage every bit a consequence of a shortage of these disquisitional materials.

Proppant: Every bit stage counts have grown, the amount of proppant, typically sand, has increased besides. Increases in pump pressure, and more perforations per lateral human foot, mean more and longer fractures. This increases the corporeality of proppant required per well. In areas such every bit the Permian Basin, ii factors–loftier drilling intensity and increased proppant per well–combine to create cost and sourcing challenges for proppants. Non only is sourcing challenging, and expensive, but trucking logistics can also be difficult.

Fluids: Frac fluid requirements are also impacted by increases in the pumping pressures and the number of stages per well. This increases the demand for frac fluid. Different sand, which is easily stored onsite, frac fluids have limited onsite storage in frac ponds. These ponds must be continuously replenished from wells, ponds, rivers and lakes. In improver, companies are increasingly treating and reusing the brackish water from producing wells. Frac fluid management–which involves sourcing water, scheduling recycled fluids that cannot be stored in frac ponds, and moving water between ponds as needed, and scheduling the wells that consume the fluids–can be a very tricky process to manage. Of course, with idle costs of $100,000-$250,000 per day during the frac process, running short of frac fluid can be a costly fault.

Well Completion Technology

Well Completion Technology encompasses the post-obit steps:

- Creating the Authority for Expenditure (AFE);

- Designing the Completion Process: Perforation Design, Pump Schedule and Completion Procedure;

- Sourcing the Materials, especially fluids and proppants;

- Orchestrating the Various Service Providers, particularly the frac coiffure, drill-out, frac data/consulting, tubing, and assembling the Christmas tree;

- Orchestrating the daily and summary drilling reports and their distribution both internally and to Not-Operating partners (NonOps);

- Collecting field cost estimates and forwarding those to accounting;

- Hand-off to the Production team;

- Reviewing all service provider bills and approving them for payment;

- Assembling and analyzing all completion data in an effort to refine and optimize the process for the side by side well;

- Sharing all completion data with NonOps.

Completion engineers must also stay abreast of the latest developments in technique, materials and engineering. This tin can be achieved by socializing with services providers who work on other operators wells, data sharing with other operators where the company may have a NonOp position or a data sharing relationship, talking with vendors, attending seminars and conferences, and socializing with other operators over beers. In a rapidly evolving field like completion engineering, where efficiency can mean the difference between making a profit or a loss, staying informed is a critical part of the completion engineer's job.

Well Completion Design

Well completion design involves 3 primary processes: perforation ("perf") design, pump schedule, and a completion process clarification. The completion process description and pump schedule tend to vary little from i well to another. However, the perf blueprint varies based on diverse aspects of each well.

The first step of perforation blueprint is to define the maximum completable length. This takes into business relationship a number of variables, such equally hardlines, buffers, product height, trigger toe information, dogleg severity, and more. One time you have the maximum completable length, and its location on the directional survey, you can start to design your perforations.

Perf design so involves a number of variables such as plug showtime, cluster spacing, stages, clusters per phase, stage spacing, perfs per cluster, and more. In this phase, engineers may use a standard model. However, the adjacent phase involves fine-tuning that model based on wireline information collected most the well.

The engineer and then looks at gamma ray, gas content, lithology and a number of other variables as an overlay to the standard perf programme. Then he fine-tunes various variables to create the perfect perf design for this well.

Once the plan is finalized, he generates a detailed perf plan along with the materials list for perforating the well, such equally perf gun requirements.

Well Completion Reporting

Well completion reporting is the process of collecting and distributing activity, cost, materials, and operational information from the completion procedure. Groups such as IADC, PPDM, and Energistics accept attempted to institute various standards for coding, modeling, formatting and transmitting sure aspects of this data. Earlier generations of well reporting focused exclusively on delivering a study in newspaper or PDF format. 2d generation solutions add the ability to export completion data to spreadsheets for what-if analysis, creating key metrics and loading into data visualization packages like Spotfire. The newest generation of reporting software leverages a database management organisation (DBMS) that can produce reports and spreadsheet consign, while calculation the ability to store far more data, query, filter and dispense the data, and besides enable data sharing between various departments inside the operator, also equally NonOps and information sharing partners. For more insight on this topic, run across the Spreadsheet vs. Database commodity.

During the well completion procedure, the wellsite managing director typically tracks activities and costs in a daily completion report and toll report respectively. This also rolls into a completion summary report. These reports serve a variety of valuable functions every bit described below:

- Understanding the progress, problems, and productivity of the team.

- Awareness of the efficiency of the service providers

- Every bit a tool for evaluating your field operations and service providers

- Understanding the cause of any delays, cost overruns, and issues

- Sharing the reports with NonOp partners

- Establishing the value of the asset, when selling it

- Post sale, providing the buyer with the information he needs to optimize new wells and to maintain existing wells

- For workover crews to sympathise what is downhole, prior to working on it

- Providing information to the various regulatory agencies

- As background material for capital-raising efforts

Completion reporting is one aspect of the completion information menstruum. It starts with ingesting the drilling data, so that you can melody the completion accordingly. The adjacent aspect is the completion design process, and the data it generates. Then you have the real-time completion data, which may be monitored and/or candy in real-time. Then comes the reporting process and the data it generates. After this comes the information sharing with NonOps and data sharing partners. Finally you have the mail service job data analysis, where you lot generate key metrics, comparisons, data visualization and more than, enabling y'all to appraise the efficiency of the processes and methods, which is used to optimize time to come wells. Then the data is handed to the product team, so that they tin can optimize maintenance and production of the well. As you lot can see, the completion report isn't just a certificate, but just 1 phase of the flow of data.

Well Completion Optimization

Well completion optimization is the assay of completion information, in guild to improve well productivity, while reducing well costs. As stated higher up, the primal to E&P profitability in tight oil & gas wells is operational efficiency, doing more than for less. While some E&P companies look for the fixed cookbook for a particular geology, area or basin, the most effective operators are constantly pouring over internal and external data in gild to notice new and better methods.

At a typical price of $6M-$9M per onshore horizontal well, almost companies are unwilling to examination significant changes to their processes, they instead prefer to employ stepwise improvements. At the same time they learn from others what has worked in similar geologies. The combination of various stepwise advances has resulted in very impressive cumulative advances in efficiency.

Well completion optimization is a data driven procedure that requires the post-obit:

- Data Quality

- Data Depth

- Information Breadth & Variability

Information Quality: The old adage garbage-in, garbage-out applies here. If your information is wrong, your results will be incorrect. Software tools, internal processes and solid data quality command are required to ensure that y'all beginning with high-quality information.

Information Depth: This substantially refers to how much data you collect. You volition want to blend operational data (e.g. pressures), with materials data (proppant types and amounts), activity data (processes used on the well), production results, cost information, directional survey data, and diverse primal metrics derived from this data. All of this can exist used in what-if scenarios, data visualization and dashboarding, and machine learning to fuel optimization.

Information Breadth & Variability: Data latitude refers to having big numbers of wells in your system. The more wells you lot have, the more than statistically relevant the results. You also need variability between wells. If every well is the verbal aforementioned, you can have i,000 wells in the system and acquire nothing. However, a high degree of variability between wells enables you to larn what factors improve well results. This is coordinating to the favorable adaptation in evolution. If nothing changes, at that place is no way to learn how changes can touch results, so there is no optimization.

Data variability, or diversity, is disquisitional to fuel well completion optimization. Yet, this data must also exist high-quality and have sufficient depth. Public data can assistance with breadth–including many wells–but is woefully inadequate in terms of data depth. Public data tin also suffer from intentional obfuscation by operators in their reporting. For example wells might take multiple laterals, sidetracks, etc. and even so that is not identified in the data. This can upshot in erroneous insights. Erroneous results are more problematic than no results at all, since they send yous in the incorrect direction. We believe that the just solution sourcing data that offers quality, depth, and latitude & variability is through information sharing relationships.

Well Completion Information Sharing

Well data is generally shared for the following purposes:

- Shared with NonOps under standard JOA agreements

- Under data sharing agreements (bi-directional)

- Shared with the owners of mineral rights

- Shared with investors, east.chiliad. private equity investors

- Shared with potential acquirers of the asset, e.g. setting up a information room

- Shared by the service providers to the operator

Equally an operator, inbound data sharing is an excellent mode to get data that is loftier-quality, wide, and deep. When the key commuter of the E&P business was finding oil and gas, companies viewed well data equally a company hush-hush, never to be shared with competition. They wanted to buy up all of the surrounding land cheaply and over time, as their capital grew. If word got out about a major find, their competition would buy up the land around them. Today, the key driver of East&P success is operational efficiency. Most of the mineral rights have been acquired around known shale basins, and then competition for mineral rights is less of an effect. While some companies even so jealously baby-sit their procedures, most realize that the customs–employees at operators, and service companies and their employees–provide a communication channel that shares best practices. Even if a service provider adheres to a non-disclosure agreement, an operator can say, frac this well like yous did that one for my neighbour.

With the true cat already being out of the bag on best practices, almost operators recognize that data sharing is an excellent mode of accumulating superior information for evaluation and optimization. We suspect that data sharing will get standard procedure among operators.

One of the barriers to more all-encompassing data sharing is the tower of Babel issue. Most completion data is stored in spreadsheets, with each company, and sometimes each engineer, employing their own spreadsheet construction. It typically requires completely retyping the data from a sharing partner into your format, in order to make it usable. However, spreadsheets are sub-optimal tools for searching, selecting a groups of wells based on certain criteria, and then processing those wells using diverse optimization tools. The almost effective data store for optimization is a database.

Well Completion Software

There are a number of software solutions that focus on well completion data. The service providers have software specific to their office (e.thou. FracFocus). There are various tools for treatment SCADA data from smart devices. Activities and cost reporting tools are bachelor. There are real-time tools for treatment the real-time or per second data. But the main tools used for well completion optimization are Excel or a database for information storage and manipulation, various data visualization tools (east.chiliad. Spotfire), and various motorcar learning tools (machine learning is even so early in oil & gas).

While you tin can read an in-depth analysis of the relative merits of the spreadsheet and database, hither is a quick synopsis of the relative claim:

Spreadsheet

Pros:Ideal for quick and uncomplicated data entry and calculations (e.g. key metrics). Provides a skilful visual machinery for comparing one aspect across multiple wells by simply scanning a row/column or generating a simple nautical chart.

Cons: Inefficient as data depth increases, because the user is forced to gyre far too much. Maintaining i:N and Due north:Northward relationships (e.chiliad. 1 well:100 stages) is difficult and makes the spreadsheet difficult to maintain. Terrible at selecting wells based on various criteria, filtering wells, getting to a working set of wells. Not designed for data sharing and access rights command.

Database

Pros: Ideal for massive depth and breadth of data. Designed for iterative well selection, based on any number of criteria, filtering and processing across big data. Designed for managing rich relationships (1:1, 1:N, N:N) and providing granular admission control, which is required for data sharing. The database can likewise output spreadsheets, making information technology an ideal data storage and processing tool.

Cons: Requires more technical expertise to pattern and build, merely applications built on databases tend to be more user-friendly than spreadsheets. The typical user can quickly add a new formula in a spreadsheet, merely requires help to work with a database.

The Futurity of Well Completion

Drilling is a fairly mature process. While drilling continues to benefit from advancements in technologies and methods, the area where we see the most rapid advancements and the biggest opportunity for optimization is in the completion phase. Since it is advancing most apace, information technology is the phase where optimization can deliver the biggest gains in efficiency at this time.

Nosotros envision a day when extensive wireline information volition inform completion design, with more variation from stage to stage. In effect a completion design that is optimized for the specific characteristics of each well. We agree with Marker Mills, that continued advances will enable shale wells to rival the economic science of conventional wells over time. We also believe that advances in engineering science will brand more than shale basins economic to drill at low oil and gas prices. In curt, we run across a brilliant future that benefits from riding the applied science curve toward cheaper and more efficient solutions.

Source: https://deepdata.com/well-completion/

0 Response to "How to Read Completion Report Oil Gas"

Post a Comment